|

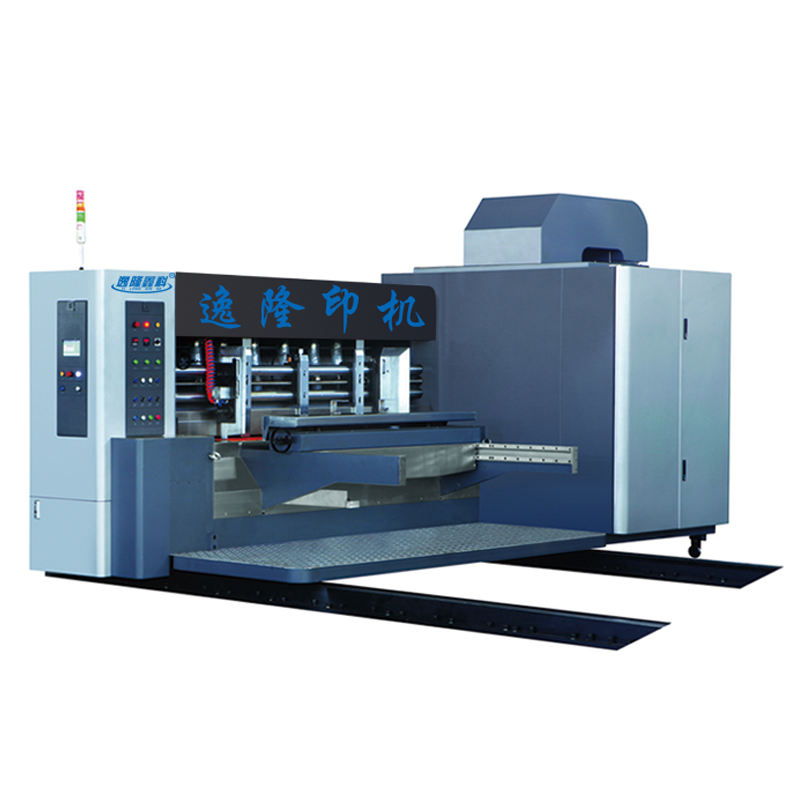

全程真空吸附水性印刷开槽模切机 (前缘送纸)

收藏

商品说明

功能与特点: ◆整台机器严格按照欧盟CE安*标准设计,具有规范化、通用化、人性化。依据人机一*化制造理念,能直接在触模屏上进行设定、修正、执行、更换、记忆等功能,是一款具有很高性价比产品。 ◆触摸屏人机界面对话和电动控制双系统操作功能,具有智能化归零、记忆自动复位、存储订单等功能;可选配远程跟踪服务系统。 ◆人机界面显示器、PLC控制器、变频器、伺服驱动器,均选用德国西门子、德国博世力士乐、日本安川等世界知名品牌。 ◆主传动齿轮采用﹙20CrMnTi﹚精品合金钢,经程控自动渗碳淬火、磨削加工处理后,保证齿面硬度均匀一致,达到六级标准精度其齿面硬度﹙HRC58-62﹚。 ◆所有辊、轴类内孔均进行切削加工,保证壁厚均匀一致、确保高速运转时平稳可靠;在加工过程中,经过多次调质处理消滁应力变化,通过磨削加工后表面进行镀层保护。 ◆应用免键连接器,消滁传统连接所产生的间隙,保持机器印刷套色长期准确。 ◆传动润滑机构采用喷淋式防溅装置;润滑系统自动循环,并装置防渗漏油机构。 ◆全程真空吸辅传送,避免拉纸轮损坏印刷版面图案,并使印刷套印准确度得到进一步保证。可选配密封腔双刮刀系统;可加装红外线烘干机构。

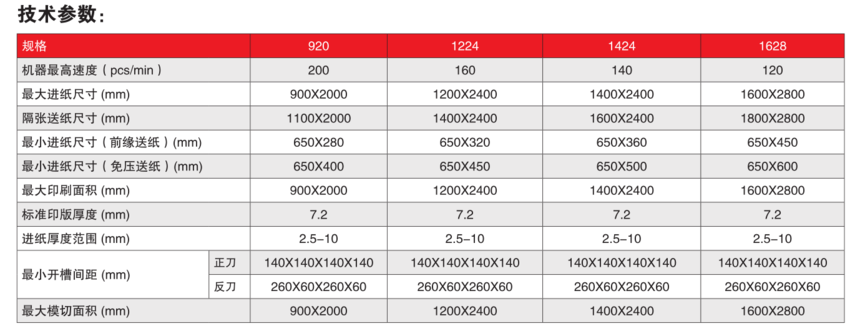

商品参数

送纸单元 Feeder unit ◆ 伺服控制前缘进纸机构,具有响应速度快、定位精度高、系统稳定好、使用寿命长等特点, 保证了机器长期使用稳定性。 ◆ 用电子凸轮替代复杂的机械凸轮控制,输纸轮轴与电机轴采用同步带连接,消滁了送纸轮 工作中的所有间隙,有*提高送纸准确度,并可避免纸板左右跑偏现象。 ◆ 真空吸辅风量变频调节;设置连续输送和隔张送纸功能;设置上吸尘除屑机构,并可自动进 行风量调整。 ◆ 采用独特的快换式半轮结构,使进纸轮圆面磨损均匀一致,保证送纸位置的长期一致性;更换 胶轮时只须直接卸装,方便、快捷减少辅助时间,使机器使用更*全、经济。 ◆ 可设定订单数量,完成后自动停止进纸输送;左右挡板、后挡板工作位置电动调整,自动侧齐 纸工作频率可任意设置;能实现同自动上料机之间联动工作。 ◆ 传送纸胶辊前、后双轴构造,保证走纸准确一致性;胶层为内软外硬结合型,具有良好的伸展性 和耐磨性。 The servo control leading edge feeding mechanism has the characteristics of fast response, high positioning accuracy, good system stability and long service life, which ensures the long- term stability of the machine. Using electronic cam instead of complex mechanical cam control, the paper feeding wheel shaft and motor shaft are connected by synchronous belt, which eliminates all the gaps in the paper feeding wheel, effectively improves the paper feeding accuracy, and avoids the left-right deviation of the paperboard. Variable frequency adjustment of auxiliary air volume of vacuum suction; continuous conveying and sheet feeding functions; upper dust cleaning and chip removal mechanism, and automatic air volume adjustment. The unique quick change half wheel structure ensures the uniform wear of the round surface of the paper feeding wheel, and ensures the long-term consistency of the paper feeding position. When replacing the rubber wheel, it only needs to unload directly, which is convenient and fast, reduces the auxiliary time, and makes the machine safer and more economical. The order quantity can be set, and the paper feeding can be stopped automatically after completion; the working positions of the left and right baffles and the back baffles can be adjusted electrically, and the working frequency of the automatic side leveling paper can be set arbitrarily; the linkage work with the automatic feeder can be realized. The front and back double axis structure of the paper roller ensures the accuracy and consistency of paper feeding; the adhesive layer is a combination of soft inside and hard outside, with good extensibility and wear resistance.

印刷单元 Printing unit ◆触摸屏、电动按钮双系统控制印刷相位、轴向位置;印版辊具有擦版记忆自动复位功能。 ◆操作部设置墨辊及墨泵启、停功能;每色组设置急停保护开关。 ◆网纹辊送纸部联动升降工作,着墨时同印版间隙电动调整;印版辊同走纸吸风箱压力电动调整,并可以分别调整风量设定。 ◆胶辊匀墨系统采用*新型工艺,在确保实地印刷同时兼容六十线以上的高网点印刷。 ◆可选配密封腔双刮刀匀墨机构,采用整体型匀墨防渗装置,避免工作时油墨外溢;其特殊刮刀角度让匀墨转移更理想, 可轻松实现100线网点印刷,并可延长刮刀和网纹辊的使用寿命。 ◆印刷相位附电磁离合器制动机构,机台分离时可自动锁住齿轮位置,防止印版辊零位丢失。 ◆印版部装置电动脚踩开关,可快速挂版、调整,方便换版和擦洗工作。 The printing phase and axial position are controlled by touch screen and electric button; the plate roller has the function of automatic reset of plate erasing memory. The operation Department is equipped with ink roller and ink pump start and stop functions; each color group is equipped with emergency stop protection switch. The paper feeding part of anilox roller is linked to lift, and the gap between the plate and the inking is adjusted electrically; the pressure of the plate roller and the paper suction box is adjusted electrically, and the air volume setting can be adjusted respectively. The new technology is adopted in the roller homogenizing system, which ensures the field printing and is compatible with the high dot printing of more than 60 lines at the same time. It can also be equipped with a double blade homogenizing mechanism with a sealed chamber. It adopts an integral homogenizing and anti-seepage device to avoid ink overflow during operation. Its special blade angle makes the transfer of homogenizing ink more ideal, It can easily realize 100 line dot printing and prolong the service life of scraper and anilox roller. The printing phase is equipped with an electromagnetic clutch brake mechanism, which can automatically lock the gear position when the machine is separated, so as to prevent the plate roller from losing its zero position. The printing plate part is equipped with an electric foot switch, which can quickly hang up and adjust the plate, and is convenient for plate changing and scrubbing. 开槽单元 Slotting unit: ◆人机界面和电动按钮调整双系统操作,可完成开槽箱高、相位、轴向移动调整。 ◆配置自锁功能预压快调机构,保证了盘、轴之间长期精度,压线时减缓了对纸板的破坏。 ◆包裹了精品聚氨脂的压线上轮,保证了纸板硬度免遭破坏。 ◆设置同步联动电动轴向移动,使上下压线轮、上下开槽刀盘、导向轮同步进行调整; 自润耐磨导向机构,保证了移位长期正确和提高耐用度。 ◆压线轮轴、开槽轮轴选用精品合金钢,经表面研磨加工后镀硬铬处理;分别经过粗、 精两台动平衡设备上进行校正,保证找到更好平衡点。 ◆选用精品合金钢开槽刀,齿形刀刃宽度为7mm。 The printing phase and axial position are controlled by touch screen and electric button; the plate roller has the function of automatic reset of plate erasing memory. The operation Department is equipped with ink roller and ink pump start and stop functions; each color group is equipped with emergency stop protection switch. The paper feeding part of anilox roller is linked to lift, and the gap between the plate and the inking is adjusted electrically; the pressure of the plate roller and the paper suction box is adjusted electrically, and the air volume setting can be adjusted respectively. The new technology is adopted in the roller homogenizing system, which ensures the field printing and is compatible with the high dot printing of more than 60 lines at the same time. It can also be equipped with a double blade homogenizing mechanism with a sealed chamber. It adopts an integral homogenizing and anti-seepage device to avoid ink overflow during operation. Its special blade angle makes the transfer of homogenizing ink more ideal, It can easily realize 100 line dot printing and prolong the service life of scraper and anilox roller. The printing phase is equipped with an electromagnetic clutch brake mechanism, which can automatically lock the gear position when the machine is separated, so as to prevent the plate roller from losing its zero position. The printing plate part is equipped with an electric foot switch, which can quickly hang up and adjust the plate, and is convenient for plate changing and scrubbing.

模切单元 Die cutting unit: |